The current flow measurement of large-diameter ventilation ducts mainly considers energy efficiency, instrument installation, and maintenance to ensure that the measurement can meet the operational requirements of the factory building. According to the structure, the most widely used are plug-in flow meters and non-contact flow meters, which can minimize pipeline pressure loss, save resources, and facilitate equipment maintenance in the later stage. The author mainly explores the application of thermal mass flow meters in flow measurement of large-diameter ventilation pipelines, mainly focusing on instrument structure and principle analysis, instrument technology development, and ventilation flow application analysis.

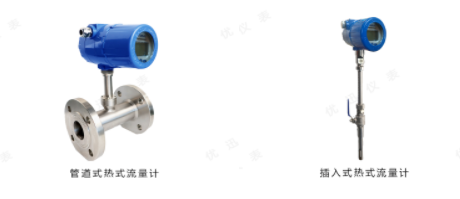

1. Structure and Principle Analysis of Thermal Mass Flowmeter

Thermal Mass Flow (TMF) is an instrument that achieves pipeline flow measurement based on the principle of heat transfer. Its theoretical basis comes from the Dunkin's law, and currently the most widely used instruments are the constant power method and the constant temperature difference method. The working principle of King's Law is to place two temperature sensors in the pipeline fluid, one of which is used to detect the fluid temperature T1, and the other sensor is electrically heated with a certain power to make its temperature T2 higher than T1. As the pipeline fluid flows, it continuously carries away heat, and the temperature T2 decreases. The flow rate of the pipeline can be calculated based on the temperature difference.

2. Analysis of Technological Development and Ventilation Flow Application

At the beginning of the 20th century, Thomas, an American, designed a plug-in flow measurement instrument for gas media, which is very suitable for large flow measurement. This type of flow meter directly contacts the heating coil and temperature measuring resistor with the measured gas, which inevitably brings a series of problems such as corrosion, wear, and explosion prevention. In the 1950s, a boundary layer flowmeter was developed to overcome the defects of Thomas flowmeter, but the flow measurement results are easily affected by fluid physical parameters (such as thermal conductivity). With the progress and development of science and technology, the demand for detecting the flow rate of large-diameter gas used in industrial production is becoming increasingly urgent. In 1992, Kurz improved and designed a new structure of thermal mass flow meter, which rapidly developed upon its release. It has now been widely used in flow measurement of large diameter gas pipelines in various fields, especially in the field of ventilation pipelines.

The research on thermal mass flowmeter in China is mainly after 2000. Scientific research institutions and universities such as the Mining and Metallurgy Research Institute, the Chinese Academy of Sciences and Huazhong University of Science and Technology are conducting research on thermal gas mass flowmeter, and have made certain achievements. After nearly 20 years of research and development, the technical research of domestic thermal mass flowmeter has also developed rapidly, The market share of foreign products is still relatively high, and currently only a few domestic manufacturers are engaged in production, resulting in a relatively low market share of domestic products.

The biggest characteristics of the application of thermal mass flow meters are high accuracy, large range ratio, simple structure, small pressure loss, easy installation and maintenance, low failure rate, good accuracy and repeatability, and are not affected by temperature and pressure. However, the response speed of instrument detection is relatively slow. When applied in large-diameter ventilation ducts,

The measured results will be affected by the irregular flow velocity distribution in the flow field, and it is necessary to adjust the instrument detection plan, such as using multi-point thermal instruments, increasing the number of detection instruments, etc., to improve the detection accuracy of such instruments in the application of irregular flow fields in large-diameter ventilation pipelines. The current research directions in the field of thermal mass flow meters both domestically and internationally are mainly focused on the following aspects:

a. The sensor structure of the thermal mass flowmeter is improved to improve the measurement accuracy and enhance the environmental fitness;

b. Research signal processing methods, such as using compensation algorithms or using different devices to process output signals:

c. Improve the development of multi-point thermal mass flow meters to better adapt to the measurement of gas flow in large-diameter pipelines.